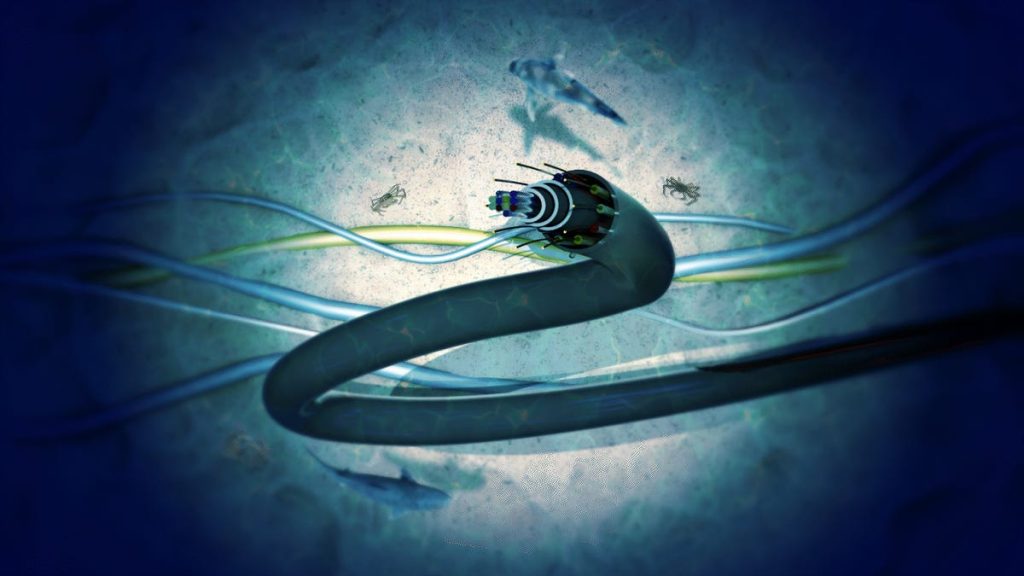

The concert takes place in London. You’re watching live from your home in Atlanta. Making this possible is a network of undersea cables that drapes the cold, dark contours of the ocean floor, transmitting images and sound at the speed of light through glass fibers as thin as a human hair but thousands of miles long.

The cables are only as thick as a garden hose and are a high-tech marvel. The fastest is the newly built transatlantic cable Amitié, funded by Microsoft, Meta and other companies, which can transmit 400 terabits of data per second. If you’re lucky enough to have a high-end gigabit service, that’s 400,000 times faster than home broadband.

However, submarine cables were also lower-tech, coated with tar and deployed by ships using essentially the same process that laid the first transatlantic telegraph cable in the 1850s. SubCom is a submarine cable manufacturer headquartered in New Jerseyevolved from a rope manufacturer whose factory was located next to a deep-water port for easy loading onto ships.

While satellite links are becoming increasingly important to orbiting systems such as SpaceX’s Starlink, undersea cables remain the workhorse of global commerce and communications, carrying more than 99% of traffic between continents. TeleGeography, an analytics firm that tracks the business, knows of 552 existing and planned submarine cables, with more being built as the internet expands to every corner of the globe and into every corner of our lives.

You probably know that tech giants like Meta, Microsoft, Amazon, and Google run the brains of the internet. Known as “hyperscalers,” they operate hundreds of data centers containing millions of servers. You might not know that they also increasingly control the nervous system of the internet.

“This entire network of undersea cables is the lifeblood of the economy,” said TeleGeography analyst Alan Mauldin. “It’s how we send emails, phone calls, YouTube videos and financial transactions.”

According to Telegeography, two-thirds of traffic comes from hyperscale providers. SubCom CEO David Coughlan said data demand from hyperscale enterprise submarine cables has surged 45% to 60% annually. “Their potential growth is pretty staggering,” he said.

The data needs of hyperscale enterprises are not only driven by their own content needs, such as Instagram photos and YouTube videos that are viewed around the world. These companies also often operate cloud computing businesses, such as Amazon Web Services and Microsoft Azure, which are the foundation for millions of businesses’ global operations.

“As the world’s demand for content continues to increase, you need to have the infrastructure in place to meet that demand,” said Brian Quigley, who leads Google’s undersea and terrestrial networks.

First undersea cable spans major communications routes including London New York. These remain vital, but newer routes are taking bandwidth away from the beaten path: the west coast of Greenland, the volcanic island of St. Helena in west Africa, the southern tip of Chile, the Pacific island nation of Sitka, a town of 8,000 people, Alaska.

This is all part of the gradual transformation of undersea communications. Cables were once the exception connecting a few important urban centers, now they are becoming a network spanning the world. In other words, despite their high cost and strange technology, undersea cables are becoming similar to the rest of the Internet.

But as more and more internet traffic flows through undersea cables, there’s reason to worry about them. Last year’s explosive damage to the Nordstream 1 and 2 gas pipelines connecting Russia to Europe was logistically more difficult than severing an internet cable as thick as a thumb. An ally of Russian leader Vladimir Putin says undersea cables are vulnerable to attack. Taiwan has 27 undersea cable connections, which the Chinese military may view as an attractive target.

“There’s a lot of talk right now about how space is the next contentious area. But I think the seafloor is going to be a very contentious area,” said Steve Bowsher, president of In-Q-Tel, In -Q-Tel is a nonprofit organization supported by the CIA. Represents the CIA, FBI, NSA and other U.S. government agencies in investing in start-up companies. “These will be targets in any form of dynamic conflict.”

The risks are clear: Vietnam’s internet performance suffered when all five cables were outage earlier this year, while a volcanic eruption on the island of Tonga knocked out most of its communications for weeks.

But these risks pale in comparison to the real benefits, from the macroeconomic to the purely personal. The network is becoming more reliable, more capable and faster, with a surge in new cables extending the network beyond its current 870,000 miles of routes, which will attract more and more countries to join.

This makes the internet richer and more resilient for all of us—including when you’re getting work done and looking for entertainment at the end of the workday.

Why submarine cables are everywhere

The economic advantages are significant. McKinsey estimates that undersea cable connections mean faster internet speeds, lower prices, job growth of 3% to 4% and economic activity growth of 5% to 7%.

At the same time that traffic demand from hyperscale enterprises is surging, telecommunications companies that have traditionally installed undersea cables have withdrawn from the market.

“About 10 years ago, a lot of traditional telecom providers started to really focus on wireless and what was happening in last-mile networks,” said Frank Rey, head of hyperscale network connectivity for Microsoft’s Azure cloud computing business. Wait times for new cables are getting longer, with the planning phase alone stretching out by three to five years. Hyperscalers need to be on top of everything.

Hyperscale initially started by investing in other projects, a natural move considering that submarine cables are often operated by consortiums of many allies. Now, more and more hyperscalers are building their own solutions.

The result: massive cable construction. TeleGeography, which closely tracks submarine cables, predicts that the world will spend $10 billion building new submarine cables from 2023 to 2025. Google-owned cables have already been built, including Curie, Dunant, Equiano, Firmina, and Grace Hopper, and two more transpacific cables are coming soon: Topaz this year, and TPU in 2025 with AT&T and other partners.

Mauldin said the cables don’t come cheap: A transatlantic cable costs about $250 million to $300 million to install.

Cables are crucial. If one Azure region fails, a data center in another region comes online to ensure customers’ data and services remain up and running. In the United States and Europe, terrestrial cables carry most of the load, but in Southeast Asia, submarine cables dominate, Rey said.

As hyperscalers dominate, pushing data instead of voice calls, undersea networks must become more reliable. Receiving a busy signal or being disconnected may be a minor annoyance, but a disruption in computer service is much more devastating. “If that number goes down, you’re going to lose your mind,” Coughlan said. “The network we create today is much better than the one we created 10 years ago.”

The origin story of undersea communications

Today’s cables can send up to 250 terabits of data per second, but their technology dates back to the 1800s, when scientists and engineers such as Werner Siemens discovered how to run telegraph cables under rivers, the English Channel and the Mediterranean Sea. Many early cables failed, in part because the weight of the cable laid on the ocean floor would tear the cable in half. The first successful transatlantic cable project failed after only three months of operation in 1858, sending just over one word per minute.

But investors eager to profit from fast communications supported the development of better technology. Higher copper purity improves signal transmission, sturdier sheathing reduces cable breaks, repeaters installed regularly along cables enhance signal strength, and polyethylene insulation replaces the rubbery material harvested from the gutta percha tree in earlier times. Material.

The telephone eventually replaced the telegraph, further advancing technology. The transatlantic cable installed in 1973 could handle 1,800 simultaneous calls. In 1988, AT&T installed the first transatlantic cable, using glass fiber optic cables instead of copper wires, an innovation that increased capacity to 40,000 simultaneous calls.

SubCom’s submarine cable factory traces its roots to rope making in the 1800s. “At that time most ropes were used on ships or needed to be transported by vessel,” said CEO Coughlan. “Transitioning into the phone cable business requires a factory in Shenzhen and Hong Kong with quick access to the ocean and winding capabilities.”

Submarine Cable Inner Technology

Fiber optic lines transmit data in the form of laser pulses. As with terrestrial fiber optic lines, using multiple light frequencies (colors, to you and me) means more data can be sent at once. Networking equipment on shore at either end of the cable encodes the data into light for transmission and decodes it after reception.

Fiber optics is great for fast broadband and long-distance data transmission, but the technology has its limitations. That’s why every 30 to 60 miles of cable has a large bump, called a repeater, to boost signal strength.

However, repeaters require power, which is where another part of the cable structure comes into play. Outside the fiber optic bundle, the copper layer can carry up to 18,000 volts of power. It is sufficient to power a repeater across the Pacific from just one end of the cable, although power can often be provided from both ends to increase reliability.

Why not keep increasing the laser power so you don’t need repeaters? Because raising it too high will eventually melt the fiber, said Brian Lavallée, senior director at networking technology giant Ciena.

His company makes networking equipment at both ends of undersea cables, using different data encoding methods — manipulating the frequency, phase and amplitude of light waves — to squeeze as much data as possible onto each fiber.

“We are very, very close to the Shannon limit, which is the maximum amount of information that can be sent through a communication medium,” Lavalle said.

How ships install submarine cables

Companies installing cables first choose a route and survey the route to avoid marine problems such as nature reserves, rugged seafloor and other cables. Finding the right route and obtaining licenses can be complex when multiple countries, telcos, and businesses are involved.

The cable itself is gradually released from a dedicated ship. It’s not as simple as untying the string when flying a kite on a windy day.

Fiber optic bundles are narrow, but submarine cables are thicker, heavier and bulkier. They are stored in metal cylinders that wrap and unroll the cable as it travels from shore to ship or from ship to ship. A single vessel’s three “tanks” can hold 5,000 tons of cable, equivalent to approximately 1,800 miles of lightweight cable and 600 miles of armored cable for busy waters.

SubCom had to figure out the order in which each cable segment would be installed and ensure that when installation began, the right end of the cable was on top of the coil. This means that while the cables are stored in SubCom’s warehouse, they must be stored “flipped” the other way around before being shipped. SubCom’s Coughlan said that when it is transferred to the ship on a cycle-by-cycle basis, it reverses direction to the correct configuration.

This is inherently complex, but weather, permitting or other issues may force changes to the installation sequence. This may require flipping the cable at sea where the two ships are abreast. In a business that is heavily digitized, it turns out to be a very analog problem, trying to account for things like a ship rocking on the high seas and the weight and bending limitations of cables.

“We have a guy who is an expert on this,” Coughlan said. “He had to be able to solve the problem with his hands and a rope first because we found that computer modeling would never work.”

Near the coast, the cables are armored with steel cables and buried on the seafloor with a special plow-shaped device towed behind the ship. Every time a new cable passes through another installed cable, the plow is pulled into the water. In deeper oceans, fishing equipment and anchors are less of a problem, and cables are less protected and simply laid on the seafloor.

Repair severed submarine cables

Undersea cables are quite strong, but one gets cut every three days or so, TeleGeography said. Fishing equipment and anchors are the main culprits, accounting for about 85% of the total reduction. Ships often anchor to ride out storms, but the storm pushes the ship and the ship drags the anchor.

Most other cuts come from the Earth itself, such as earthquakes and mudslides. Tonga is another example where a single submarine cable connection was severed by a volcanic eruption.

Man-made climate change is causing more extreme storms, and Microsoft’s Wray is concerned. “What keeps me up at night are large-scale climate events,” he said. In 2012, Hurricane Sandy severed 11 of 12 high-capacity cables connecting the United States to Europe, he said.

Most cuts occur closer to land, where there is more boat traffic and the water is shallower. There, the cables are encased in metal armor and buried under the sea, but even then, the cable cuts are a matter of when, not if. Google’s Quigley said there are typically more than 10 cables cut around the world at any given moment. The worst season for power outages is October to December due to bad weather and fishing activity.

Cable operators can pinpoint where cables are cut, but repair ships usually have to wait for government permission. Rey said the average repair time is two weeks, but repairs typically take three to four weeks, according to Takahiro Sumimoto, head of Japanese telecom giant NTT’s marine cable division. It took two months after the 2011 Fukushima earthquake.

“The water was so deep that the cable was cut into pieces,” Sumimoto said.

Repairs require a boat to fish out one end of the broken cable, often using the same type of grapple equipment that has been used for centuries. A boat buoy floats one end of the cable while the other end is retrieved. The ship splices the fibers back together and packages the splices in thicker packages.

Faster new submarine cable technology

Because cable installation costs are so high, there is a strong incentive to collect more data. There is plenty of room for more fiber, but this approach is limited by the power requirements of the repeaters.

Today’s new cables use 16 pairs of fibers, but the new cable NTT is building between the United States and Japan uses 20 pairs of fibers and can reach 350Gbps. Another Japanese tech giant, NEC, is using 24 fiber pairs to bring the speed of its transatlantic cable to 500Tbps, or 0.5 petabits per second.

“Especially after the pandemic, we are seeing capacity shortages everywhere. We urgently need to build new cables,” Sumimoto said. “It’s kind of crazy. If we built a cable, the capacity would be sold out immediately.”

As new cables are installed, it is sometimes possible to upgrade old cables with new network hardware. Lavallée said Ciena’s recent upgrade quadrupled the capacity of the fiber optic lines without requiring any changes underwater.

Microsoft is also betting on fundamental improvements to fiber optics itself. In December, it acquired a company called Lumenisity, which develops hollow fibers with tiny central air tubes. The speed of light in air is 47% faster than in glass, reducing communication delays (known as latency), which is a key limitation on network performance.

Transpacific cable latency is approximately 80 milliseconds. Reducing latency is important for time-sensitive computer interactions such as financial transactions. Microsoft is also interested in hollow fiber for short-distance fiber optic lines, as lower latency effectively brings data centers closer together for faster recovery in the event of a failure.

Additionally, there are optical fibers that have multiple data transmission cores inside instead of just one. “We can’t get any more bandwidth improvements on a single fiber,” TeleGeography’s Mauldin said.

The company confirmed that part of Google’s TPU cable will use two-core fiber, but that’s just the first step. Fiber optic company OFS launched four-core fiber this year and expects submarine cable capacity to reach 5Pbps. That’s 20 times more data than today’s new cables.

Geopolitical tensions over undersea cables

There is only one internet, but the strain manifests when it connects divided countries, such as when the Chinese government blocked Google and Facebook or American companies cut off connections to the Russian internet. These technopolitical tensions have spilled over into the world of undersea cables.

The United States effectively blocked three cables directly connecting China and the United States, causing them to be rerouted to other Asian countries. According to the Financial Times, the United States has been trying to squeeze out HMN Tech, a Chinese submarine cable installation and maintenance company developed by Huawei.

But there are many indirect connections to many other countries in Southeast Asia, and there are many more to come. “There are currently 17 new intra-Asia cables under construction, with many more yet to be announced,” TeleGeography analyst Tim Stronge said in a June blog post. When it comes to the Internet routing rules that govern traffic around the world, The borders are effectively open. In other words, the Internet itself doesn’t care where the cable goes.

New geopolitics complicates the business of SubCom, which provides services to the U.S. military as well as private companies such as Google.

“A lot of governments are exercising their power in the same way they have been in the past,” Coughlan said, and it’s not just a China-U.S. issue. Some countries, including Canada and Indonesia, are enforcing cabotage laws that require work within their territorial waters to be completed by that country’s sovereign vessels.

“That leads to a lot of complications in terms of license terms and how things work,” Coughlan said. “Cables are harder to lay because of these cabotage laws. They take longer. Some of these countries only have one ship and you Have to wait to get it.”

But in the end, the economic incentives to build cable usually prevail.

“No matter what big fight there is — a trade war, a real war — when it comes down to the local level, the local countries need these cables,” SubCom’s Coughlan said. “That’s the only reason to build this project.”

The vulnerability of submarine cables

Cable leaks are real. Anchors and fishing equipment are major risks, especially in crowded corridors with multiple cables. These cables are designed to stop corrosive salt water, not attack humans.

“It doesn’t take much to compromise these cables. The bad guys can do it,” Coughlan said. Rishi Sunak, who later became British Prime Minister, concluded in a 2017 think tank paper that undersea cables were “indispensable but unsafe”.

The Center for a New American Security, a bipartisan national security think tank, concluded in a 2021 report that undersea cables are vulnerable to attack. It simulated Chinese and Russian military operations using adversarial “red teams.” In these simulations, Chinese attacks cut off Taiwan, Japan, Guam, and Hawaii, but Russian attackers had a tougher time due to the vast number of Atlantic undersea cables.

“In the CNAS wargame, Chinese and Russian red teams launched attacks against undersea cables, specifically where they ‘landed’ ashore. In almost all cases, these attacks allowed the red teams to disrupt and degrade the United States, allies and partners CNAS senior researcher Chris Dougherty said in the report that governments are forced to react to sudden loss of connectivity, leading to confusion and distraction at a strategic level.

Sunak recommended a treaty to protect the cables, NATO military exercises to better understand their importance, and the installation of sensors on cables to better detect threats. The most practical advice, though, is simple: Build more cables for geographic diversity and redundancy.

Making undersea networks more resilient

Given the importance and fragility of undersea cables, it’s no surprise that there’s a race to make the technology more powerful.

That’s why there’s a big push to expand into new landing spots. When Hurricane Sandy hit, all of the most powerful transatlantic cables landed in New York and New Jersey. Now, more are traveling from Massachusetts, Virginia, South Carolina and Florida.

“If all the cables are traveling the same path, multiple cables will be dragged and prevented from being pulled over,” Quigley said.

Typically, carriers swap the capacity of each other’s cables to provide each other with backup data paths if the cables are cut. In fact, they don’t put all their communications eggs in one cable basket.

“People are trying to make the system more resilient,” said In-Q-Tel’s Bowsher.

Finally, the geographical diversity Sunak seeks is becoming a reality, driven by better branching technology that makes multi-station cables more economical. The new Sea-Me-We 6 cable runs from France to Singapore, passing through 17 other countries. New cables are under construction connecting Europe, Africa, the Middle East, Asia, the Americas and many island countries.

“They’re all over the world,” says Ciena’s Levallée. “These cables are really a mesh.”